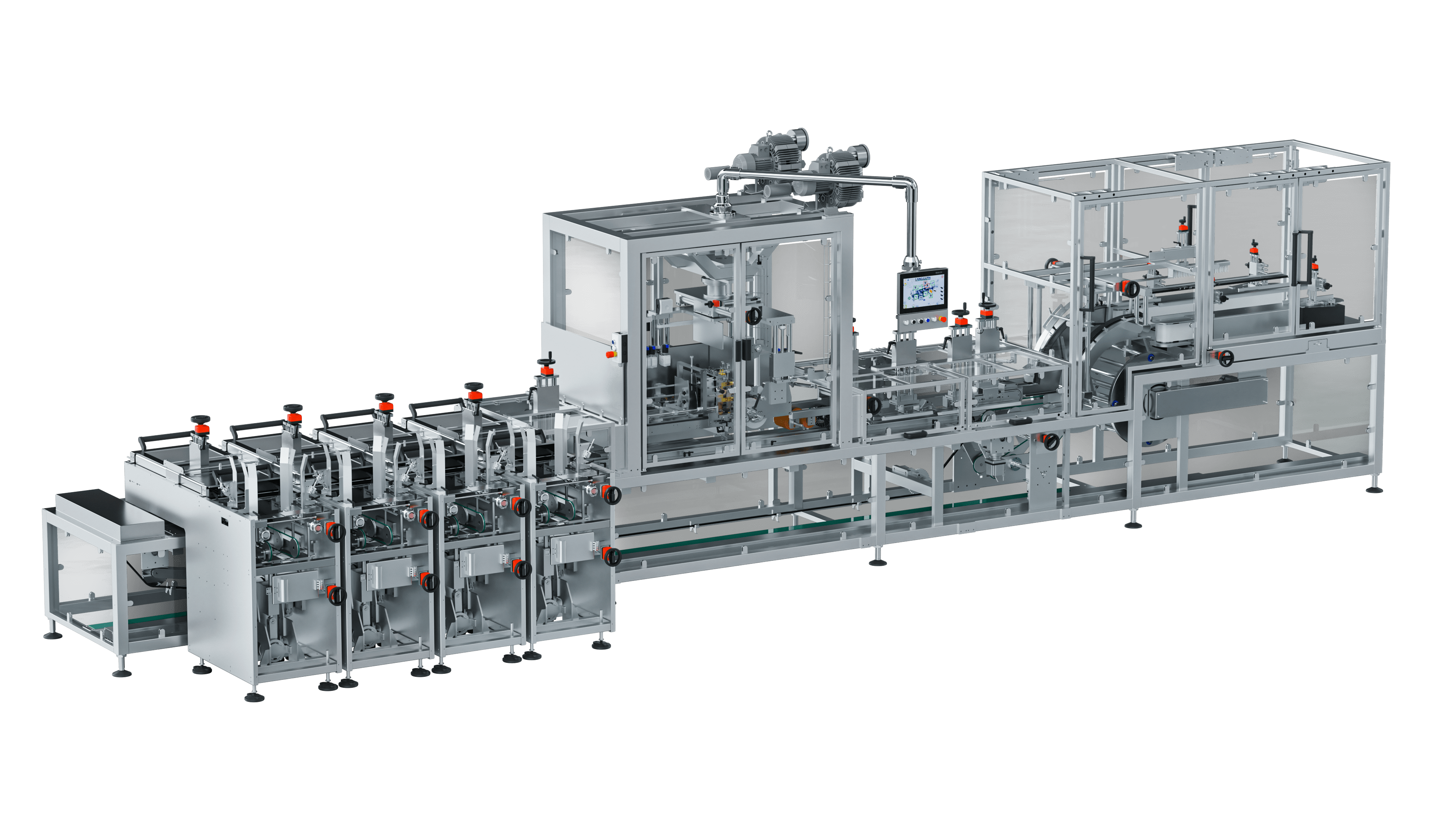

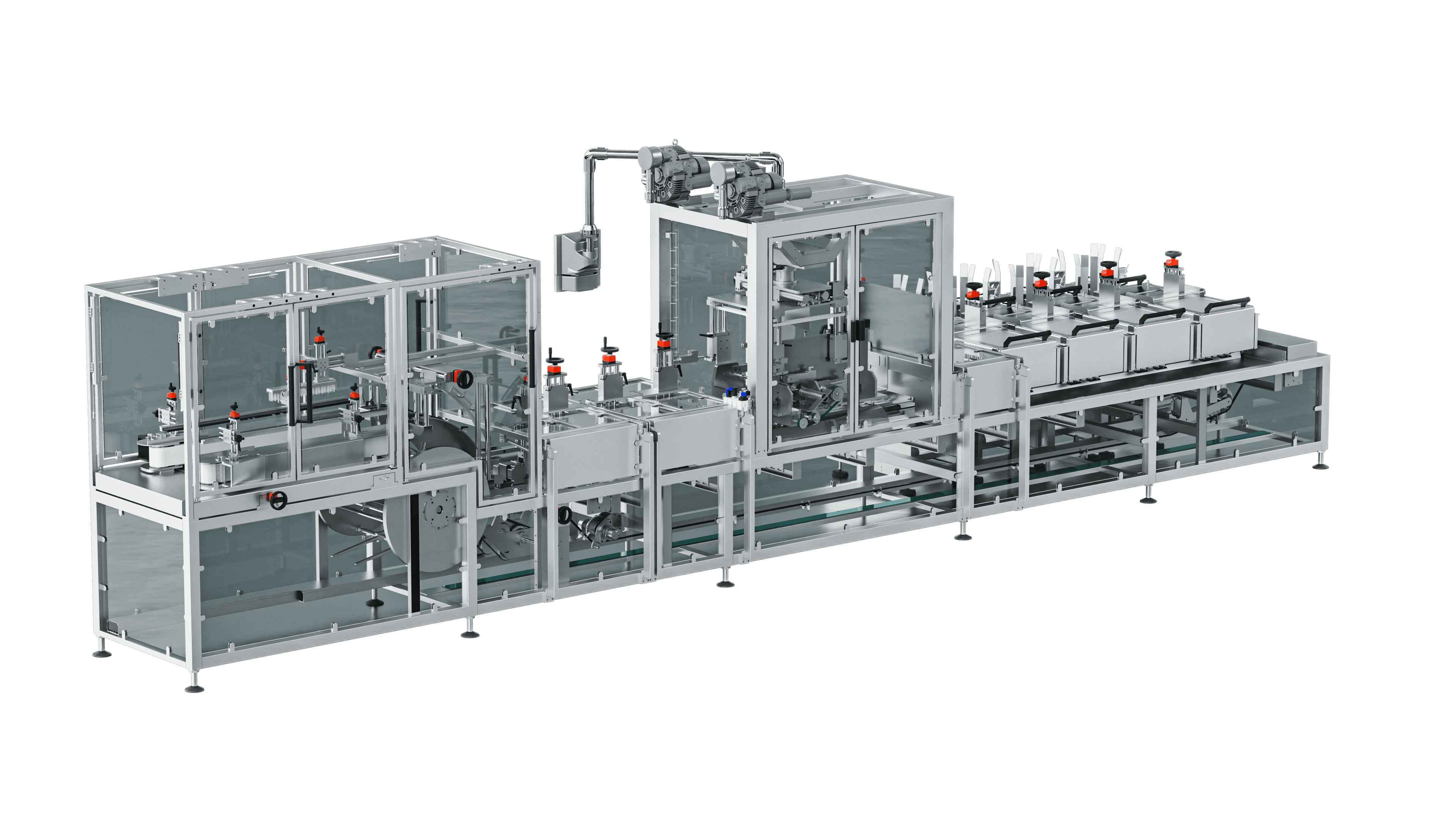

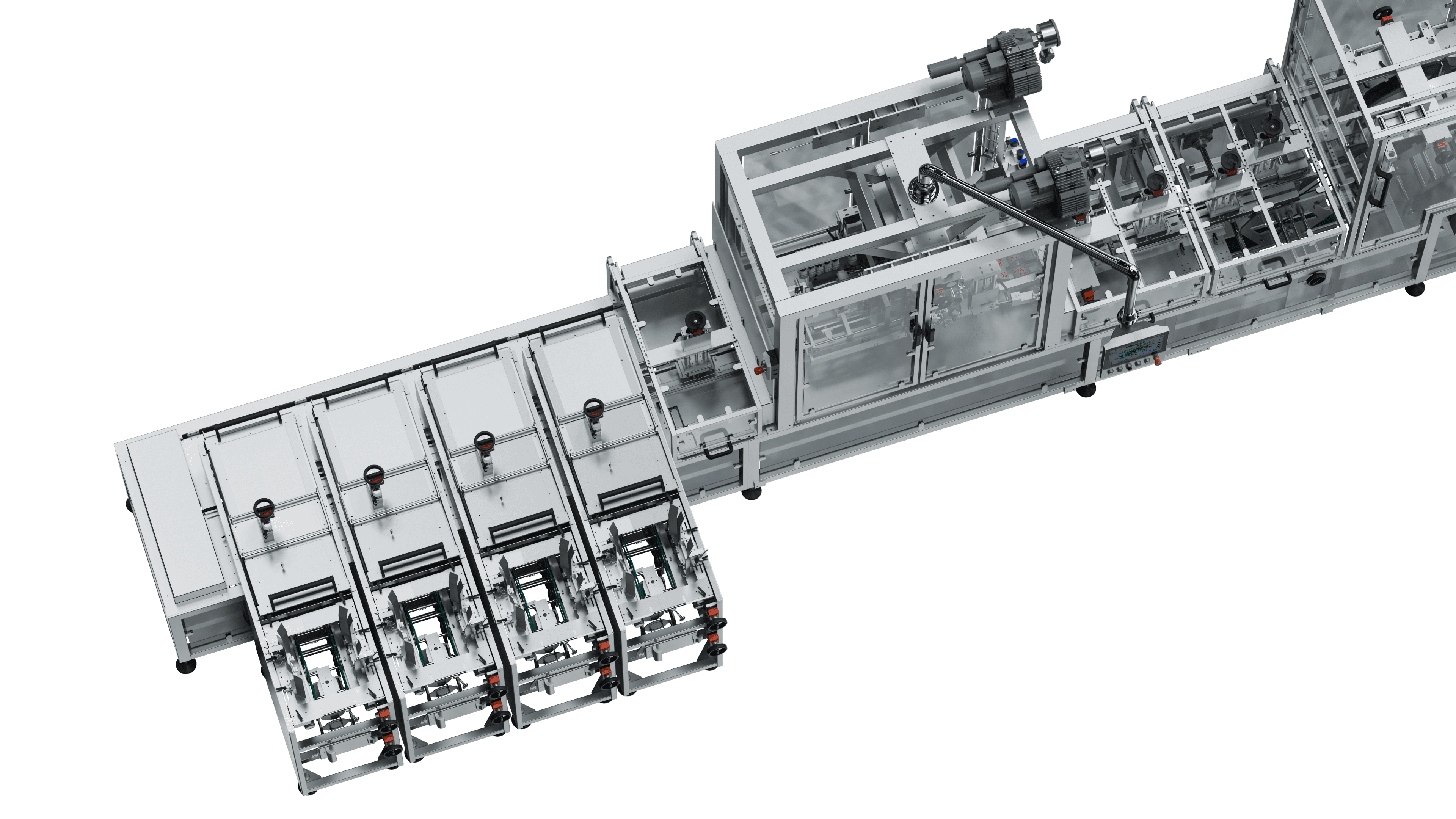

for almost all common egg carton sizes

Can be converted quickly and efficiently with only a few format parts

for integration into the existing line concept

for high economic efficiency

Product labelling with up to 150 cartons/min

| Base frame: | Welded from stainless steel |

| Machine dimensions: | L 2.435 x W 940 x H 1.385 mm (labelling station) |

| Wet glue station: | FVT18 Magazine with pneumatic glue pump |

| Hotmelt station: | FVT18 Magazine with heated glue reservoir |

| Self-adhesive station: | Type Herma or CAB |

| Packaging sizes: | 2x4 3x4 2x6 1x8 2x9 1x10 1x12 1x15 1x18 |

| Label length: | Min. 80 mm |

| Label width: | Max. 210 mm |

| Output: | Up to 150 cartons/min. |