Breweries, wineries and distilleries each represent special sectors of the beverage industry, whose products including non-alcoholic beverages place enormous demands concerning labelling.

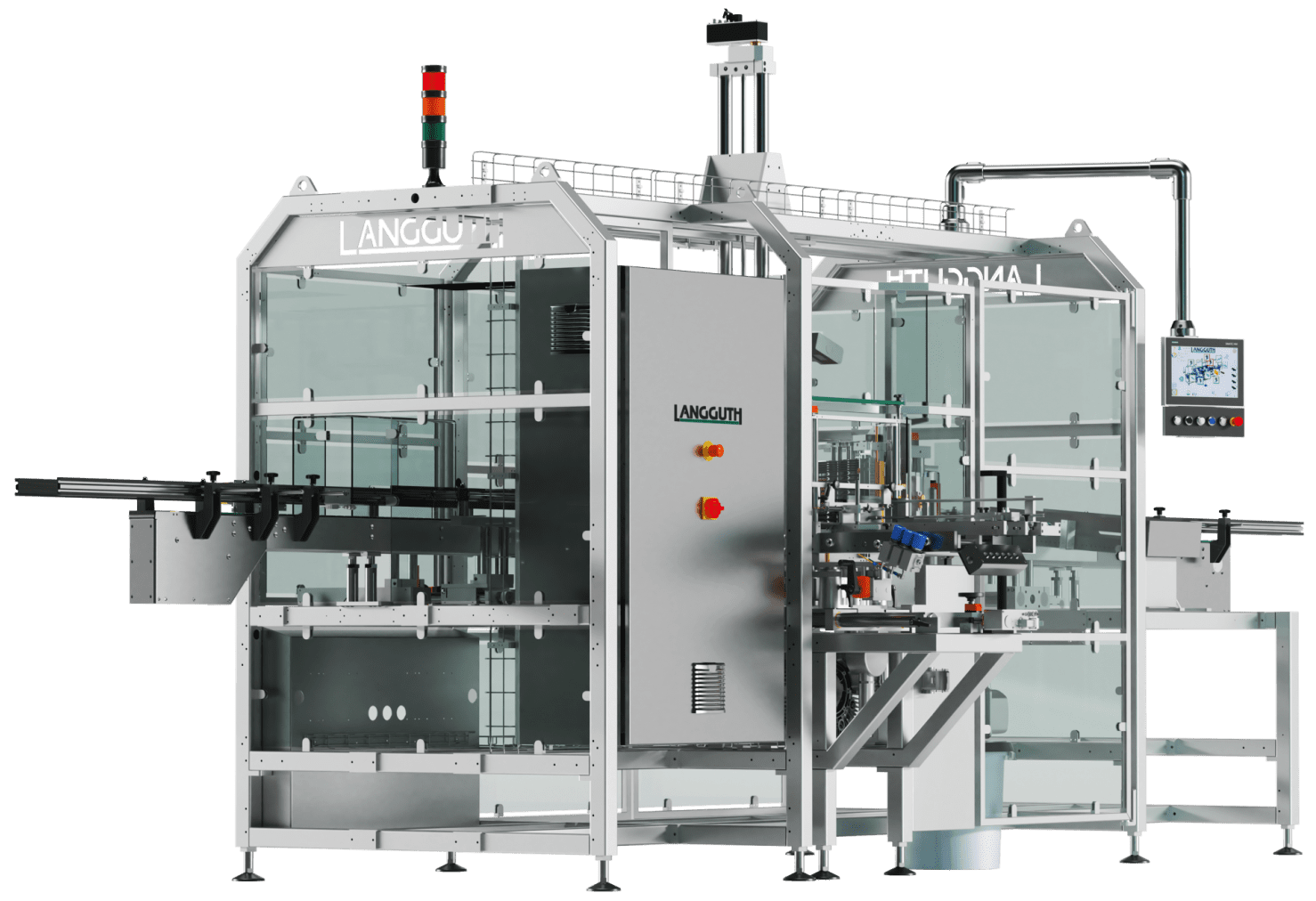

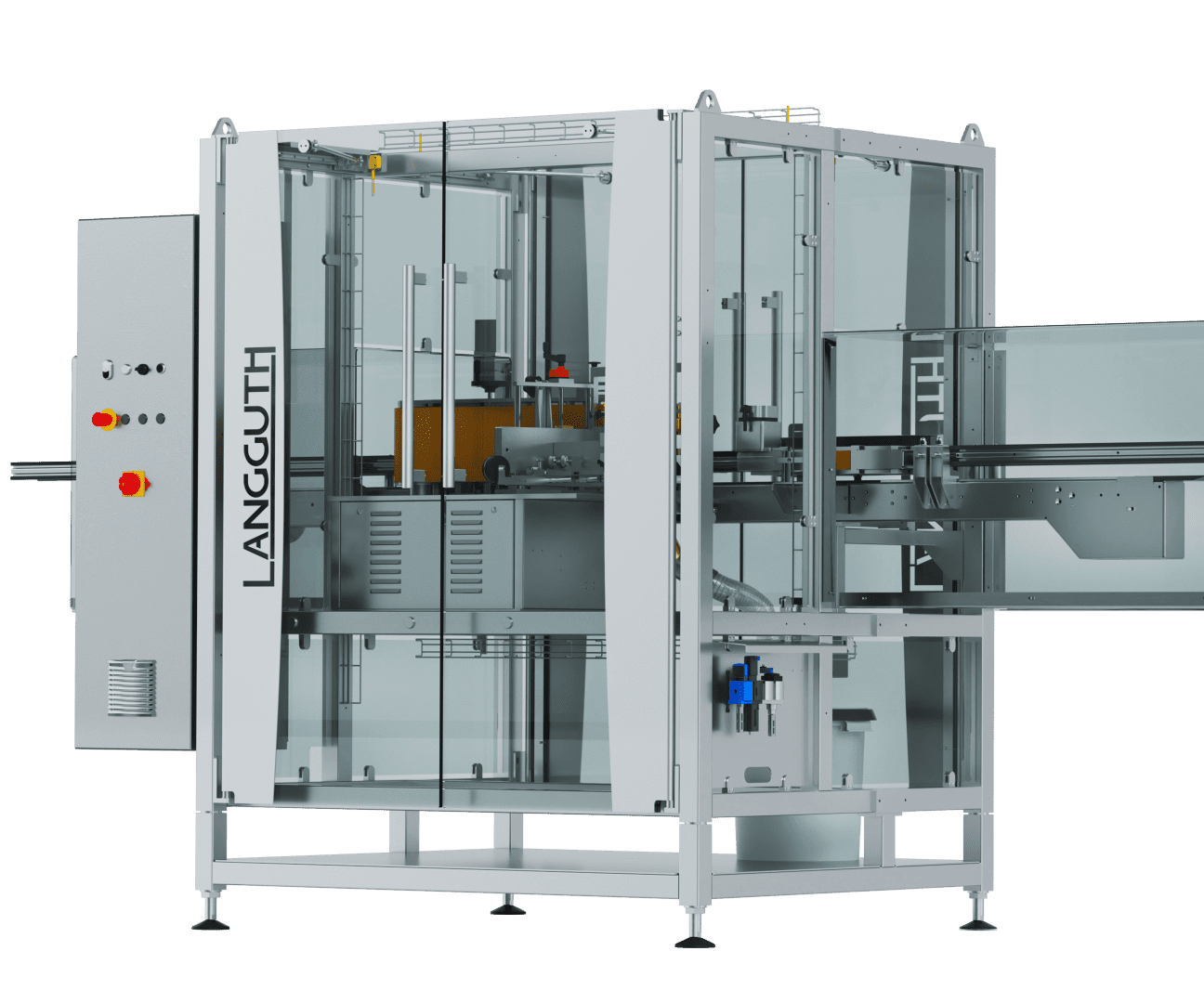

Here, the Langguth machine portfolio ranges from semi-automatic table-top labellers to fully-automatic linear labellers to classic rotary labellers up to a capacity of 500 CPM and more.

The product range includes all three labelling technologies on the respective machine types – also in combination.

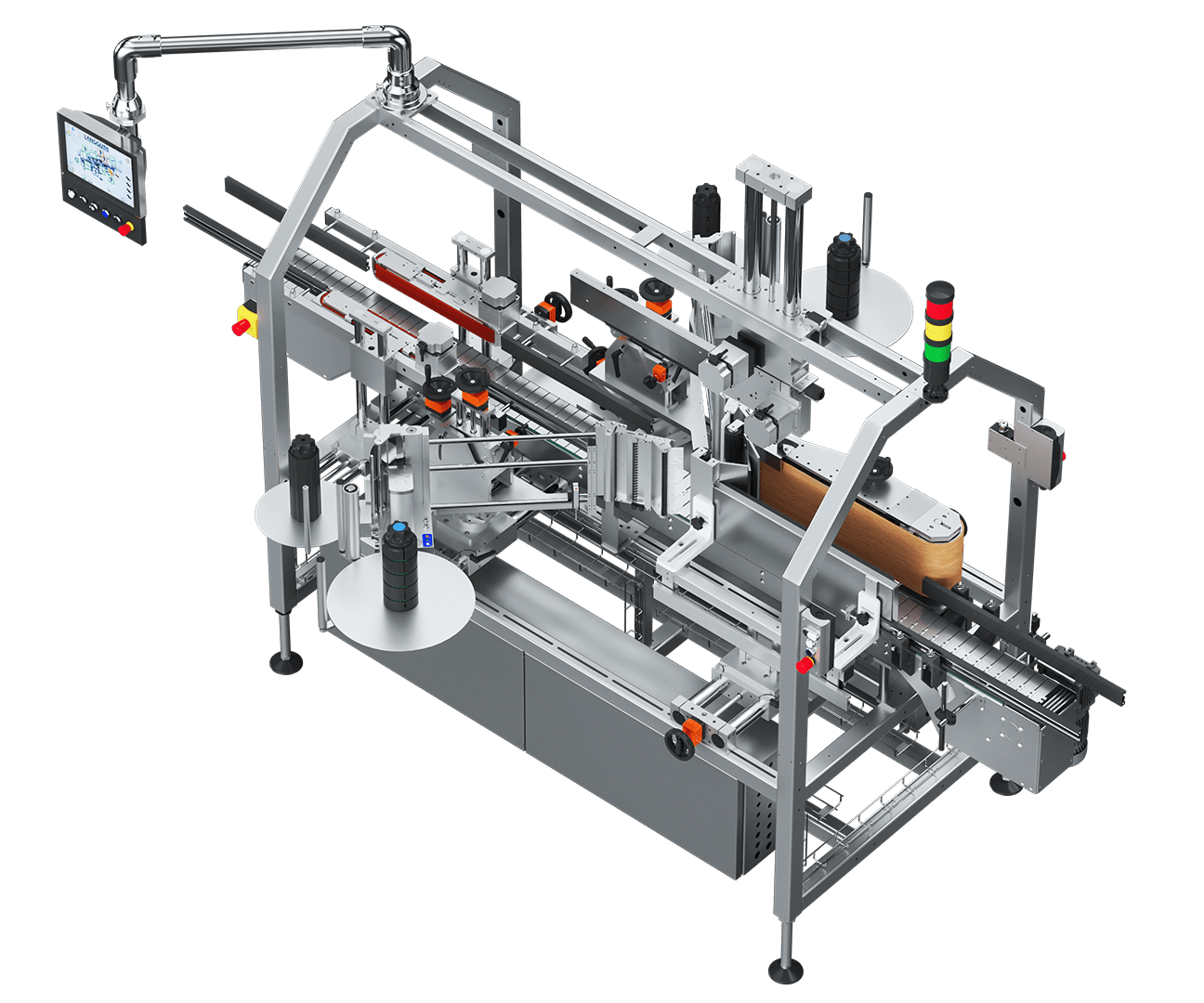

A Langguth wet glue labeller enables you to professionally label bottles and other cylindrical containers – made of glass as well as plastic. With our labelling machines for bottles, we offer you all-rounders that can be reliably used in many applications in the beverage industry – whether for wine, beer or spirits bottles. Due to the modular design of our bottle labellers, the individual extension with e.g. control components such as a label presence check is possible without any problems. The labelling machines thus grow continuously with your company.

Whether in terms of flexibility or cost-effectiveness: A bottle labelling machine from Langguth offers enormous advantages in the labelling of glass containers. Our convenient solutions set new standards in bottle labelling – you too can benefit from many years of industry know-how and professional expertise.

High-performance and precise labelling systems are essential for labelling glass bottles. Whether angular, round or oval: glass in its various shapes is not only used in the beverage and food industry but is also used for packaging pharmaceuticals and cosmetics. In addition to the precise application of labels, a labelling machine must guarantee a high cycle rate for high-volume consumer products without compromising labelling quality. This is an important criterion to ensure successful and economical production.

Equally relevant in many applications is the precise alignment of the pack, for example to visually match the fit of a wrap-around label to an additional lid or seal label. A labelling machine for bottles from Langguth enables the precise application of labels through the optimal alignment of glass and plastic bottles.

Thanks to many years of specialisation with regard to efficient labelling solutions for wineries and breweries, we can offer both fully and semi-automatic labelling solutions in this segment that are customised to your individual requirements.

Labelling bottles and jars of various geometries and sizes is a major challenge for many companies. With our labelling machines, various cylindrical products can be reliably labelled.

The advantages are the precise application of the labels and the intuitive operation with good accessibility and short set-up times. With a labeller from Langguth, you are already preparing your company for the challenges of tomorrow. Thanks to the convenient operation and a responsible partner at your side, you can concentrate on the essential challenges such as product development and increase the efficiency of your production at the same time.

In addition to the product features themselves, there are many other components to encourage a purchase decision, such as an eye-catching label on a bottle or jar. As a general rule, the more creative and eye-catching the bottle label, the greater the likelihood of a purchase by people who are not yet familiar with your brand but have simply been attracted by its appearance. To maintain the perfect finish at the point of sale, even at high labelling speeds, the quality of the labeller must be reliable.

Numerous young companies have already recognized this trend for themselves, so that solutions for professional bottle labelling are becoming increasingly relevant.

From small wineries to cooperative wineries and retailers, we already support various companies in the beverage industry along the entire process chain with comprehensive know-how in the customised labelling of bottles.

As a German manufacturer of labelling systems, we supply you with semi- and fully-automatic solutions for wineries and breweries that are best suited to your company’s needs and provide high flexibility through reliable labelling of various bottle formats.

Labelling thought holistically

As an extension, we offer you the option of adapting the labelling machine for bottles to your particular application in the best possible way with numerous components for process optimisation.

Semi-automatic labelling machine for bottles

Our semi-automatic labelling machines, such as the wetLAN 190, are perfectly suited for flexible labelling of relatively small batches and are therefore highly valued by wineries, among others. They ensure the precise application of a front and back label or alternatively an all-round label to wine, sparkling wine, and spirits bottles.

Fully automatic labelling machine for bottles

A fully automatic labelling machine for bottles from Langguth, such as the GLU|ECO® or wetLAN 110, fulfills several criteria at once that make it indispensable for use in your application – whether it is the high precision in application, the speed of production with up to 24,000 bottles per hour, the intuitive operability and maintenance, or the high economic efficiency. Automatic cleaning of the parts in contact with glue is also possible.

If you want to buy a labelling machine for bottles, feel free to contact our experts, tell us your needs and get detailed advice. In the upper part of this page you can see for yourself our labelling machines for bottles in use and also get detailed information about all offered solutions in the beverage industry.

We also offer a range of other labelling solutions for use in diverse industries.

Labelling machines for small wineries or breweries

With regard to the requirements of small wineries and breweries, we have developed semi-automatic labelling machines for bottles that can apply up to two labels to cylindrical containers.

Labelling machines for medium-sized wineries and breweries

Cooperative wineries and medium-sized breweries depend on professional and at the same time economical solutions for labelling bottles. Our fully automatic labellers such as the wetLAN 110 in the low to medium output segment reliably support the labelling of beer, wine or sparkling wine bottles with up to 7,000 containers per hour.

Our labelling solutions for large wineries, breweries and retailers

For the application of a labelling machine for large wineries or breweries, high cycle rates are necessary. In addition to the high cycle rates, our models such as the wetLAN 110 (FVT18) with GLU|ECO® gluing meet all relevant requirements in terms of efficiency, operability and reliability.

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.