Labelling has a particularly important function in the food industry. The label should not only gain a high level of attention at the POS, but also the functional properties of a DMC containing customer information messages or best before dates have to be handled by the labeller.

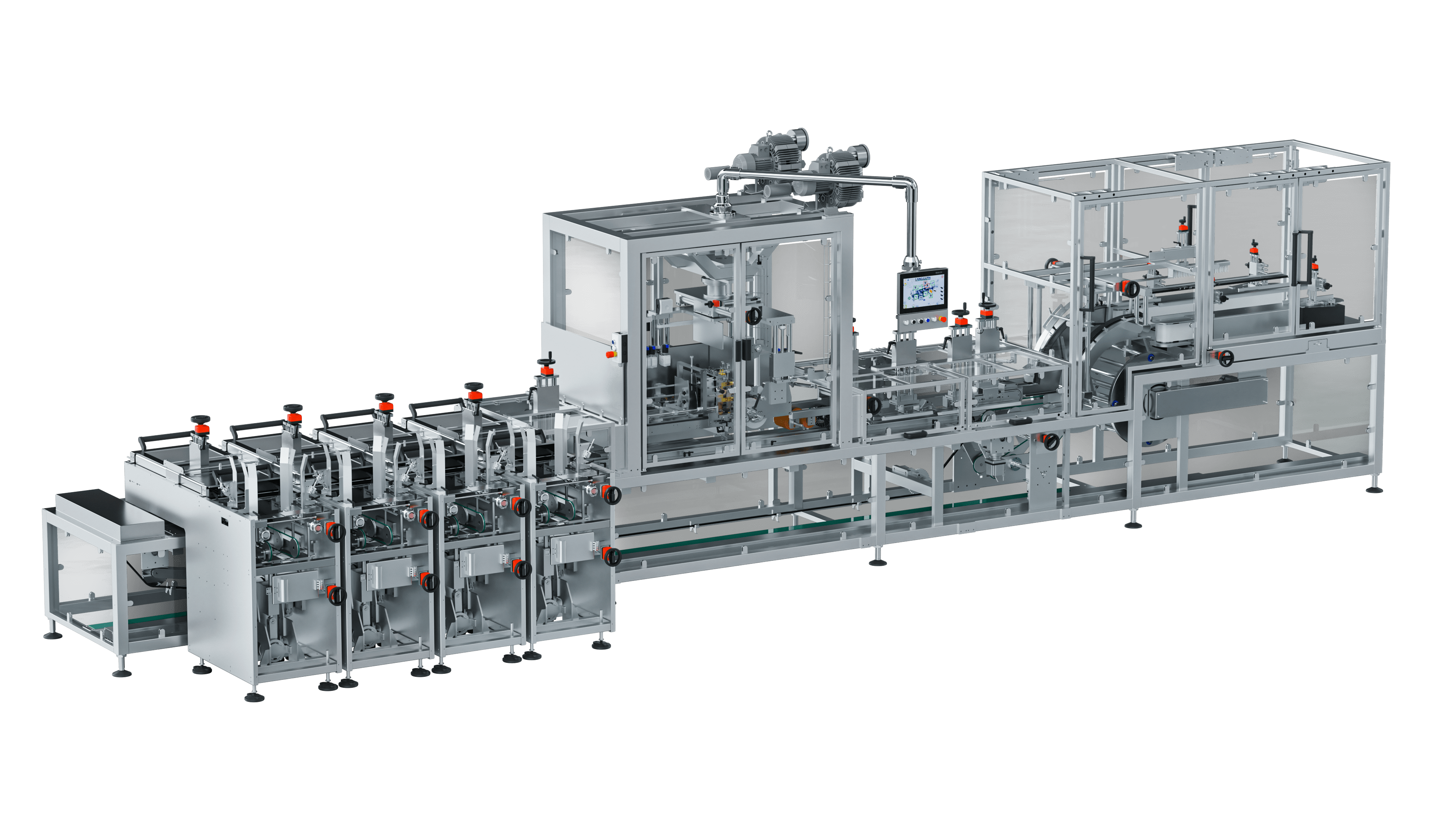

In addition to high-speed performance, production lines are also striving for ever higher efficiency criteria.

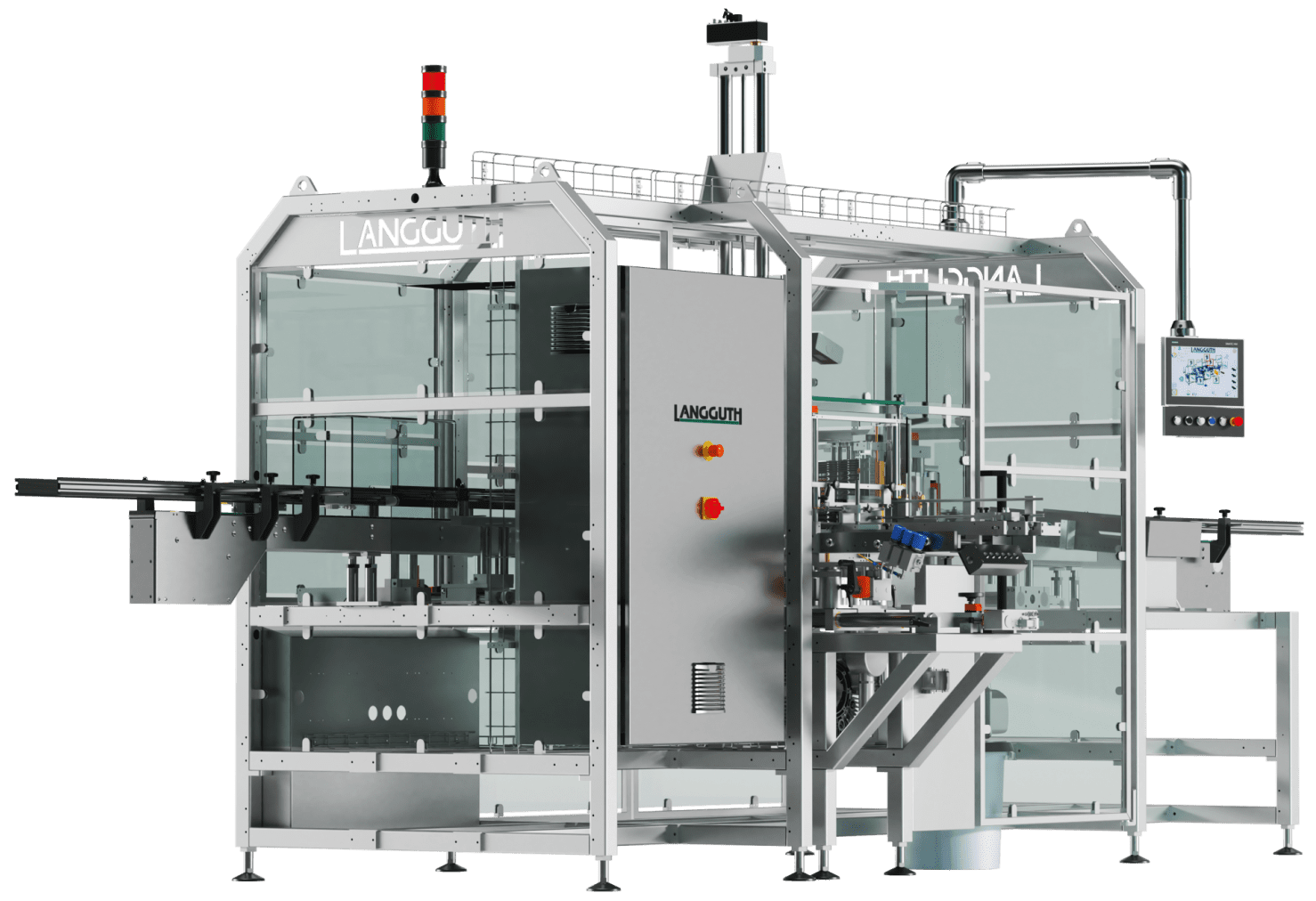

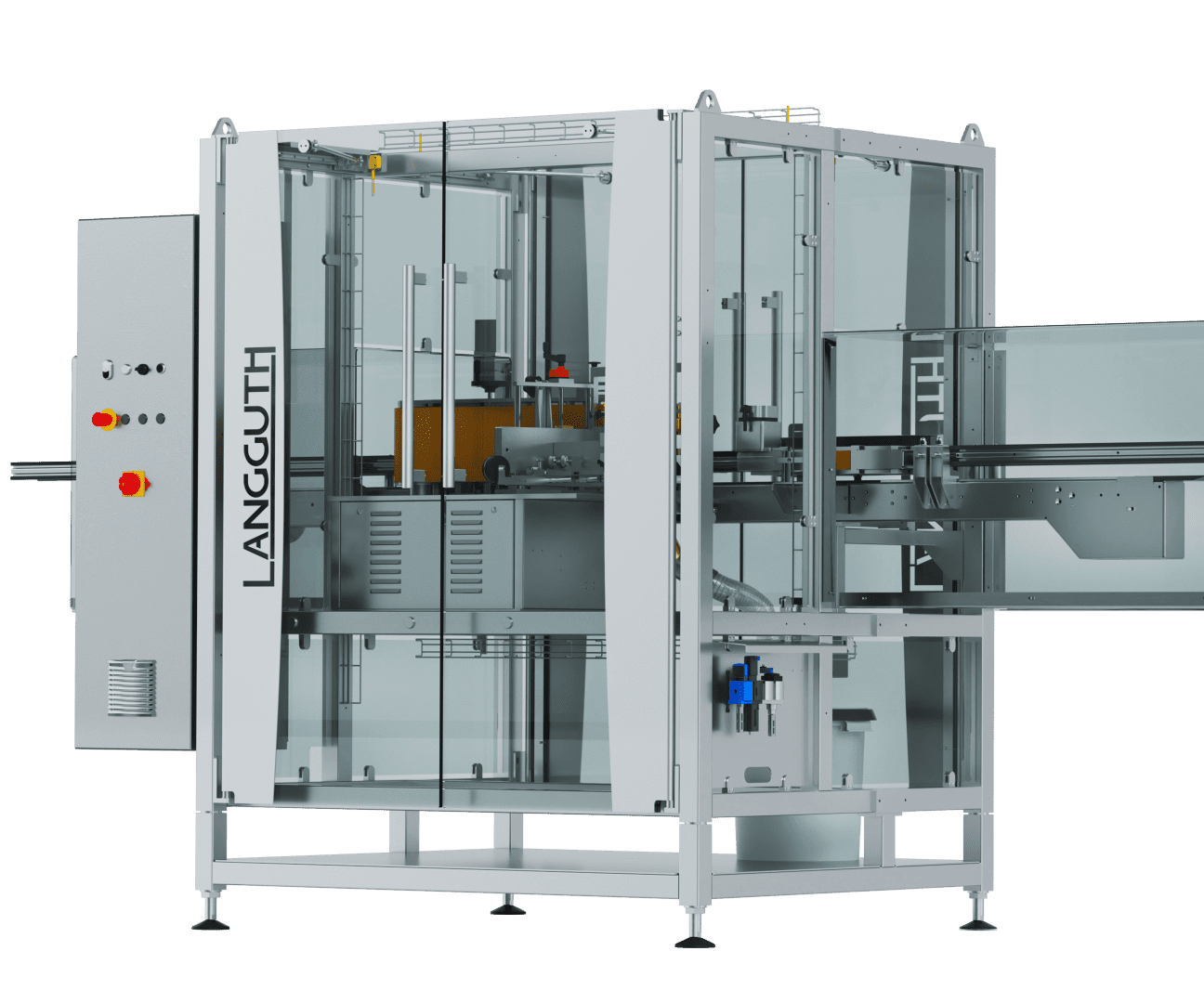

Langguth provides a lot of answers for the food industry with its versatile portfolio and offers all three labelling technologies as well as the linear and rotary machines in this sector.

Labelling machines are an indispensable element of any packaging line in the food industry. Our food labelling machines enable precise, flexible and efficient labelling of a wide variety of packages.

Thanks to their high speed, our food labellers noticeably facilitate everyday work in food production.

We will be happy to provide you with comprehensive advice on choosing a customised solution for your specific application.

Labelling has a particularly important function in the food industry. Not only the finish to attract the right attention at the POS, but also the functional properties such as the transmission of information.

Our labelling machines for foodstuffs enable the reliable application of relevant information on various packaging materials. From consumer information such as best before dates or batch number to brand logos, there are numerous reasons for pre-sale product labelling. Our labelling machines for cans, jars or cartons ensure that consumers are informed about ingredients, nutritional information, origin as well as shelf life of the products.

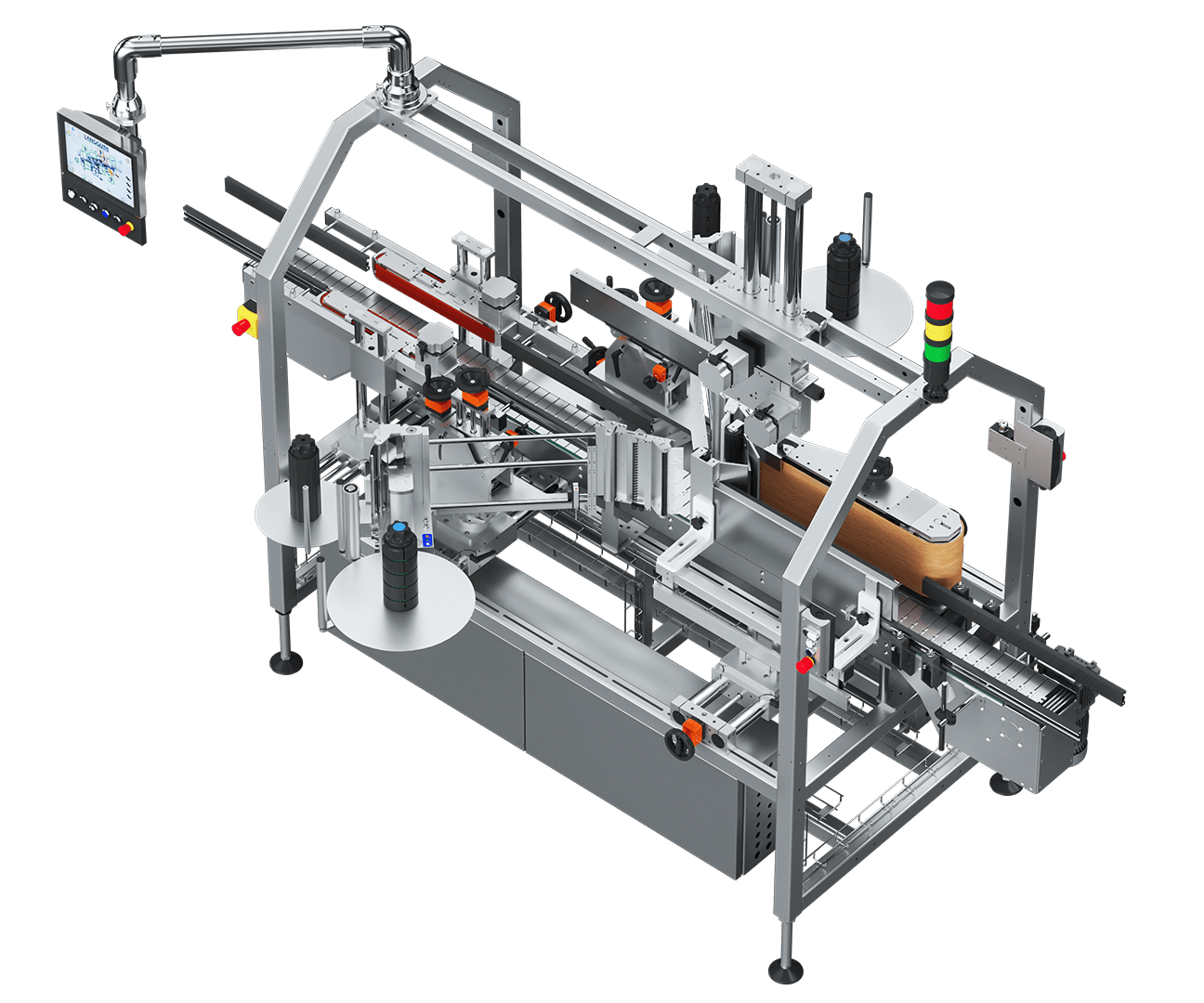

With up to 60,000 labelling processes per hour, our food labellers guarantee maximum performance in everyday work. By using our food labellers, cylindrical containers as well as cartons can be provided with different labels conveniently and time-efficiently.

In addition to legal compliance, clean labelling also promotes the overall appearance of the product and brand identity and is therefore essential for sales success.

We offer four magazine types for labelling your products – from stand-alone to high-speed requirements. We are therefore guaranteed to have the optimum labelling solution for your specific needs.

Taking ecological responsibility is more important than ever in modern production. Through the continuous development of our machines and processes, we also offer decisive support in terms of sustainability. For better compatibility between packaging and the environment, our food labellers enable the use of environmentally friendly materials and labels.

For example, with the teaching process, our labelling solutions also offer the possibility of reacting quickly to market changes and conveniently integrating new packaging into the labelling process. This enables high flexibility with regard to the integration of new, changing formats for better ecological compatibility.

When choosing suitable labelling machines, factors such as production capacity or labelling speed must be taken into account. The choice of labels also plays a decisive role.

We offer food labellers in semi-automatic and fully automatic versions.

Our semi-automatic labellers are ideal for medium production volumes, while our fully automatic labellers are designed for maximum efficiency and high speed for high production volumes.

We will be happy to help you find a solution that is ideally suited to your production needs. Feel free to contact us and let our experts advise you.

Speed and efficiency:

Our labelling machines for cans and jars can handle high production volumes in a short time. This increases production efficiency.

Precision:

Using advanced technologies, our food labellers can apply labels precisely and reliably to food packaging – for a range of different formats.

Flexibility:

Our labellers can be easily adapted to different product shapes and sizes, allowing for quick changeovers to different product lines. This efficiency means that equally innovative packaging can be quickly and conveniently integrated into the labelling process, ensuring future-proofing.

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.