Decades of experience in the paint and varnish industry allow us to be the leading manufacturer of labelling machines in this sector today.

The incredible variety of colours and countless container sizes pose enormous challenges for production – especially in view of the market’s demands for the shortest possible availability.

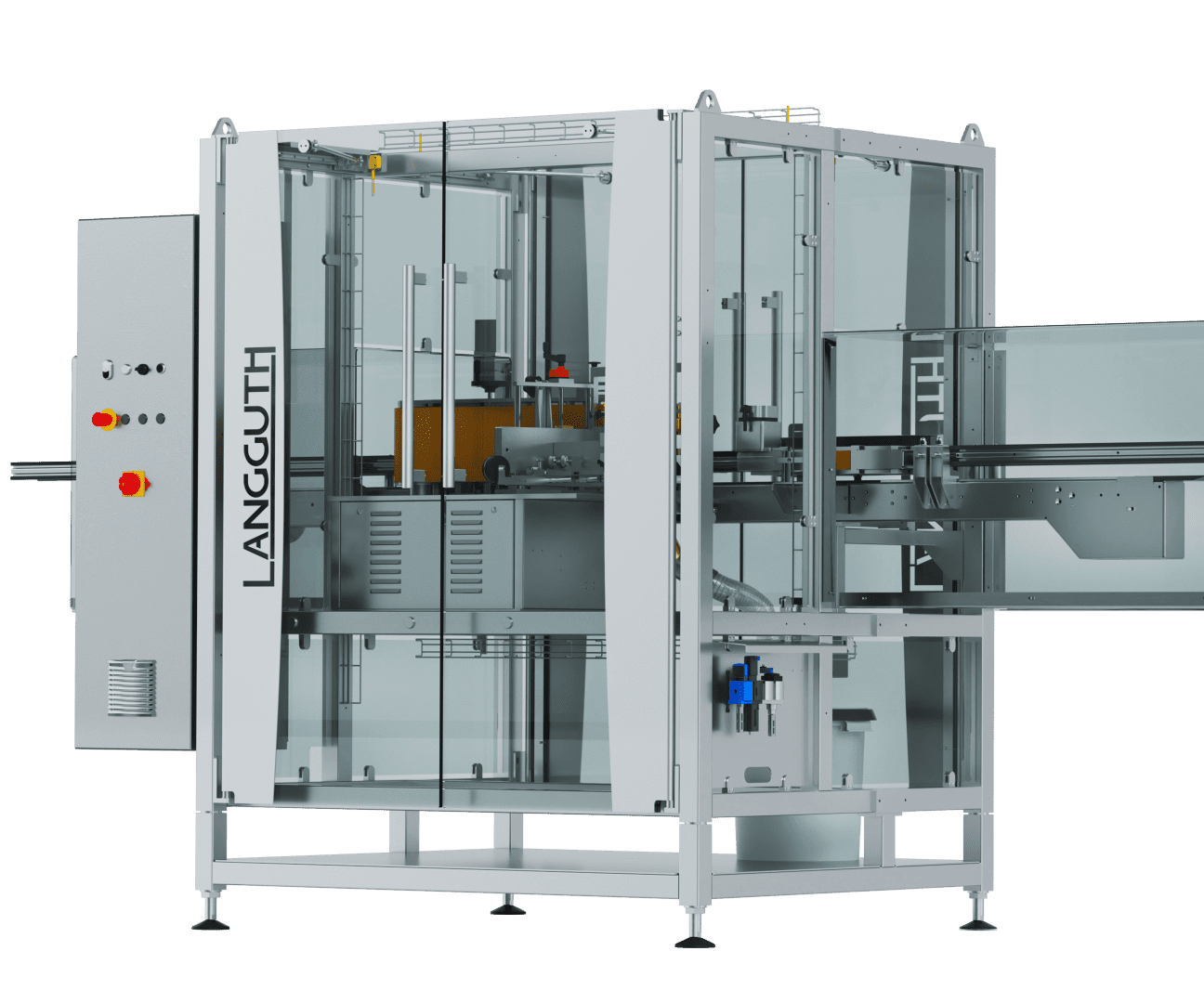

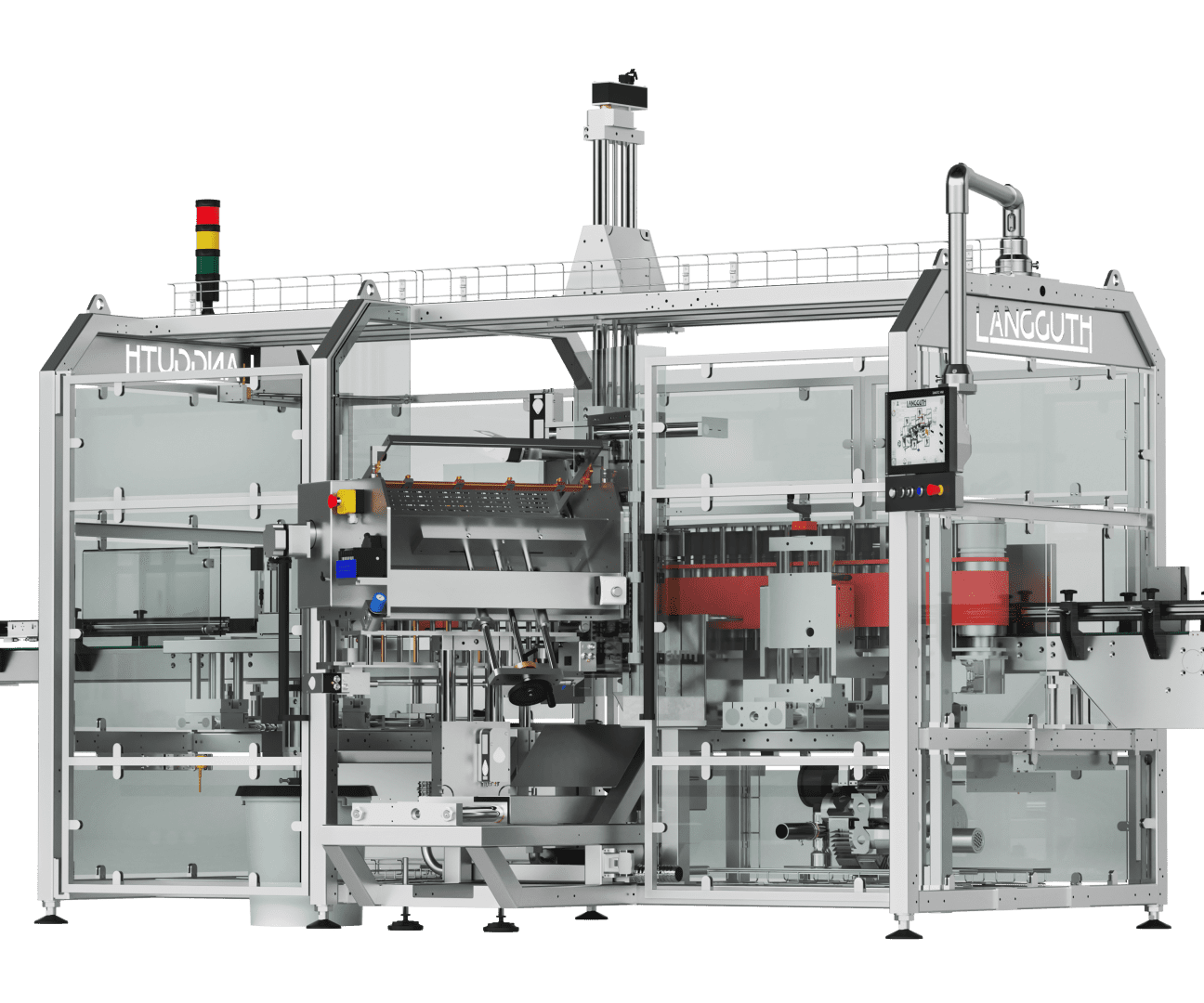

Our three Langguth labelling systems offer exactly the right solutions for the requirements of this special market. Langguth completes the product range with automatic adjustments, handling systems or other added values.

Companies in the paint and varnish industry face a number of challenges every day: One of them is the incredible variety of colours and the resulting countless formats.

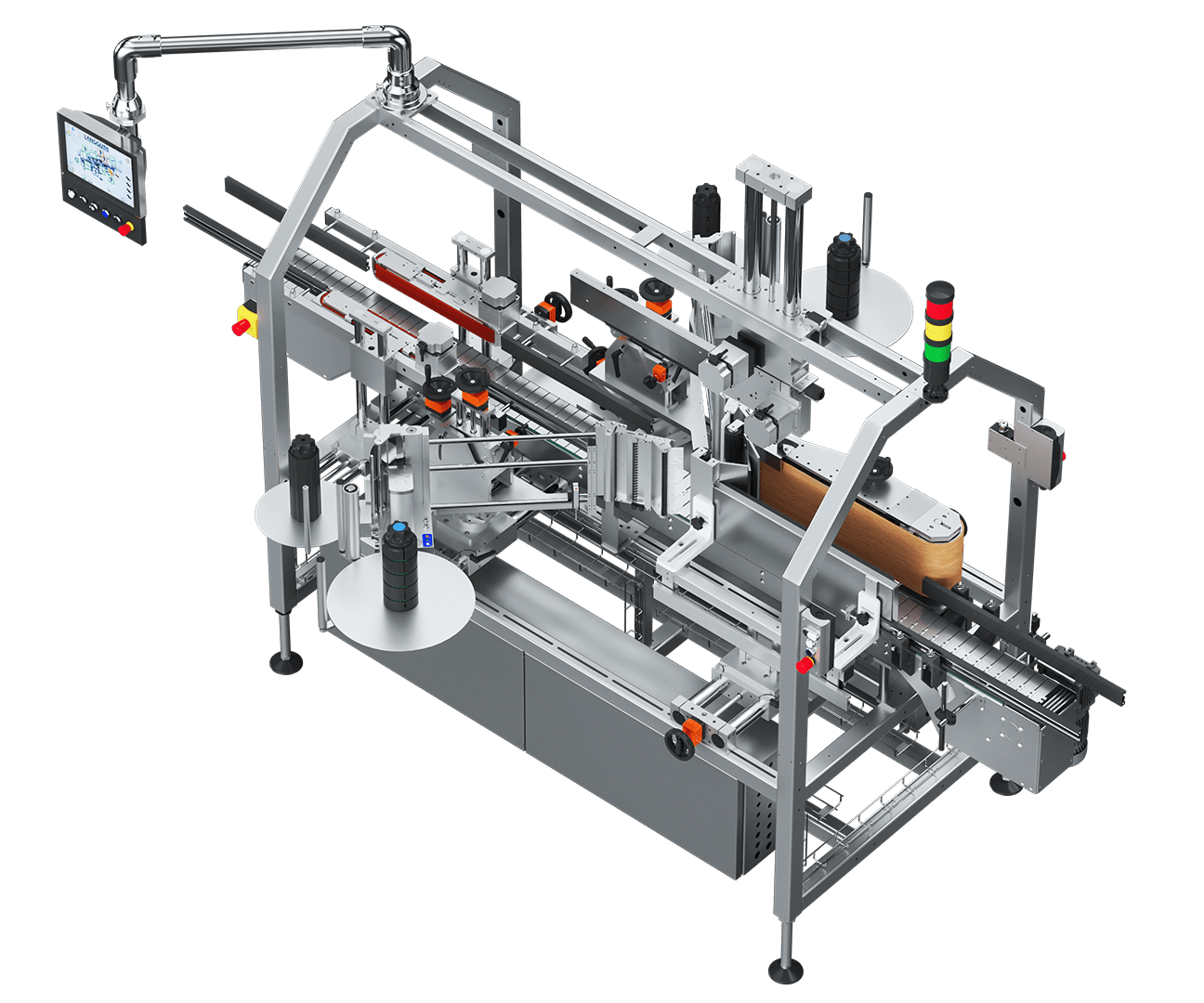

With three specialised labelling systems, precisely tailored to these requirements, we have been successfully meeting the challenges in the paint and varnish sector for years. Whether wet glue labelling, hotmelt labelling or self-adhesive labelling: Our machines process labels for small and large containers up to 30 litres and more reliably and efficiently.

For example, our wet glue labellers are capable of processing stacks of labels in both upright and lying positions, by first separating them, then gluing them and finally applying them to the respective containers. From wrap-around labels to small stickers, there are no limits for you.

Automatic adjustments or handling systems round off our product portfolio. They enable high flexibility and efficiency in production by allowing quick changeover to different container sizes and label formats. This contributes to shortening production times and increasing productivity.

Not without reason, we have been able to establish ourselves as a leading manufacturer of labelling machines in the paint and varnish industry in recent years. With decades of experience and specialised know-how, we offer customised solutions for the unique requirements of this special market.

Sustainability is becoming increasingly important in all industrial sectors, including the paint and varnish industry. With efficient and resource-saving labelling machines, we actively contribute to the optimisation of production processes and the reduction of waste. In this way, we help various companies in the paint and varnish industry to minimise environmental impacts.

Innovation is a central aspect of our work. We continuously develop our labelling machines to meet the changing requirements of the paint and varnish industry in the future. By introducing new technologies and processes, such as our new GLU|ECO® series, we actively contribute to the optimisation of production processes with accompanying efficiency increase in the paint and varnish industry.

Customer service and support are of the highest priority in our daily work. Already in the decision-making process, we offer you crucial support through comprehensive advice in the selection of a suitable labelling solution for your individual needs. In addition, we support you in the integration into your particular production line and in the training of your employees, or we undertake the commissioning completely. Even after the purchase, our reliable customer service is at your side: whether for questions, maintenance or repair.

The quality of labelling is an important factor in the paint and varnish industry, as it influences the perception and value of the final product. Professional labelling is crucial for successful sales. In addition, strict safety regulations apply in the paint and varnish industry and must be complied with.

That’s why all our manufactured labelling machines undergo strictest quality controls before delivery. In addition, after installation, we offer comprehensive training and support to ensure that you fully realise the potential of your machines and that consistently precise labelling is guaranteed.

Regular maintenance of our machines also guarantees high quality and accuracy in labelling in the long term.

We are at your disposal to discuss your specific requirements and to find the best labelling solution for your specific production line. Contact us today to learn more about our innovative solutions for the paint and varnish industry. We are happy to help you increase your productivity and achieve your sustainability goals.

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.