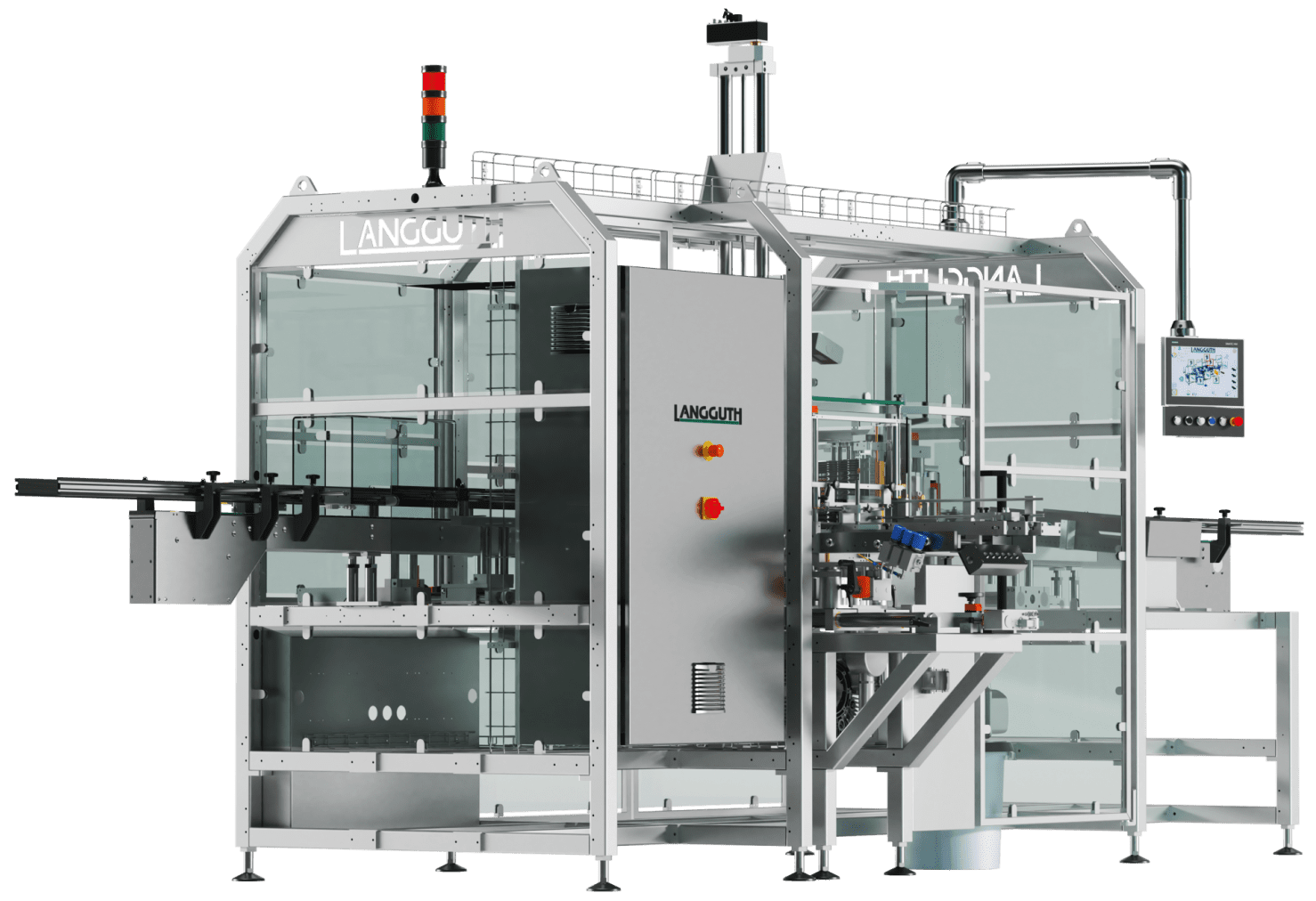

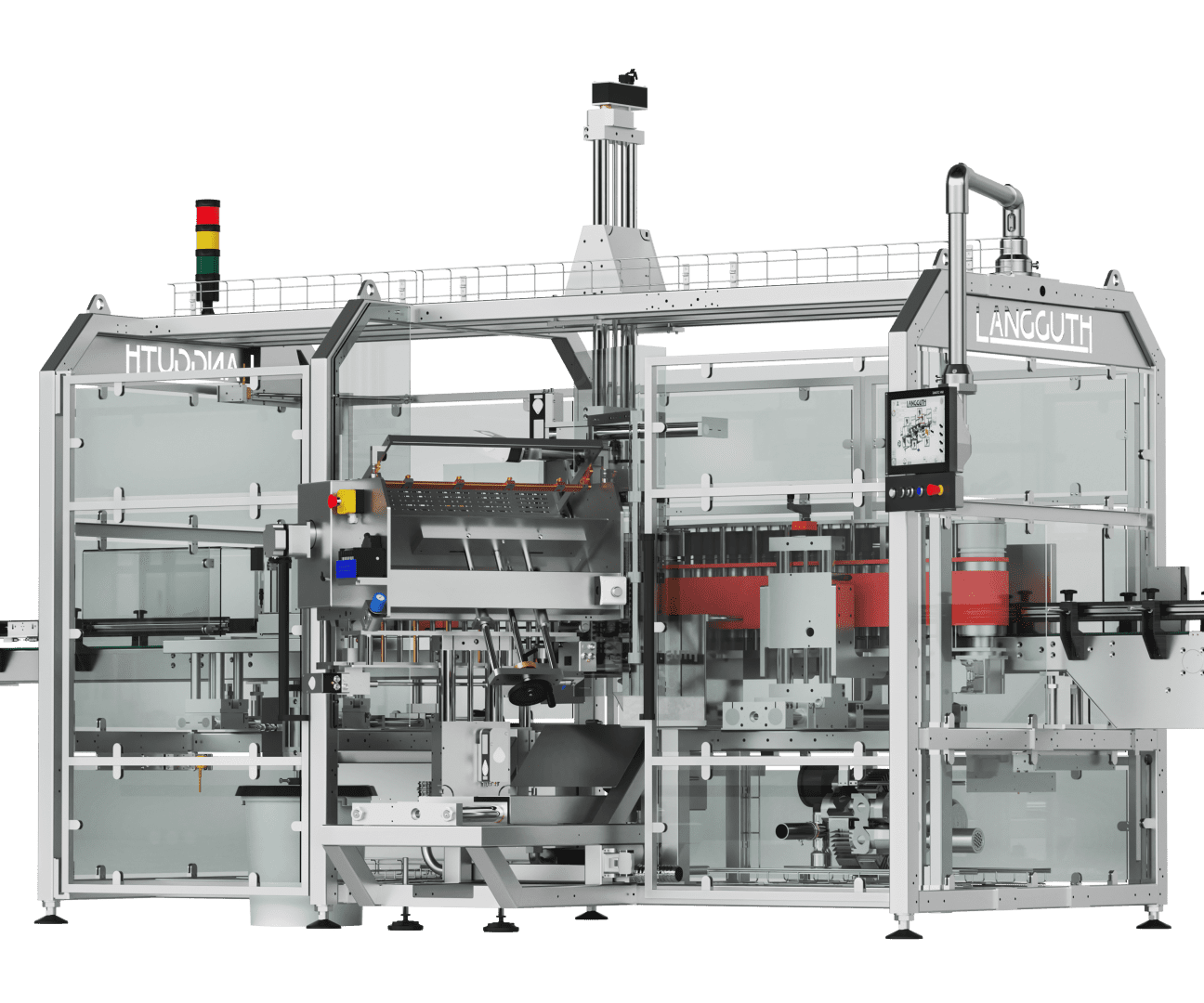

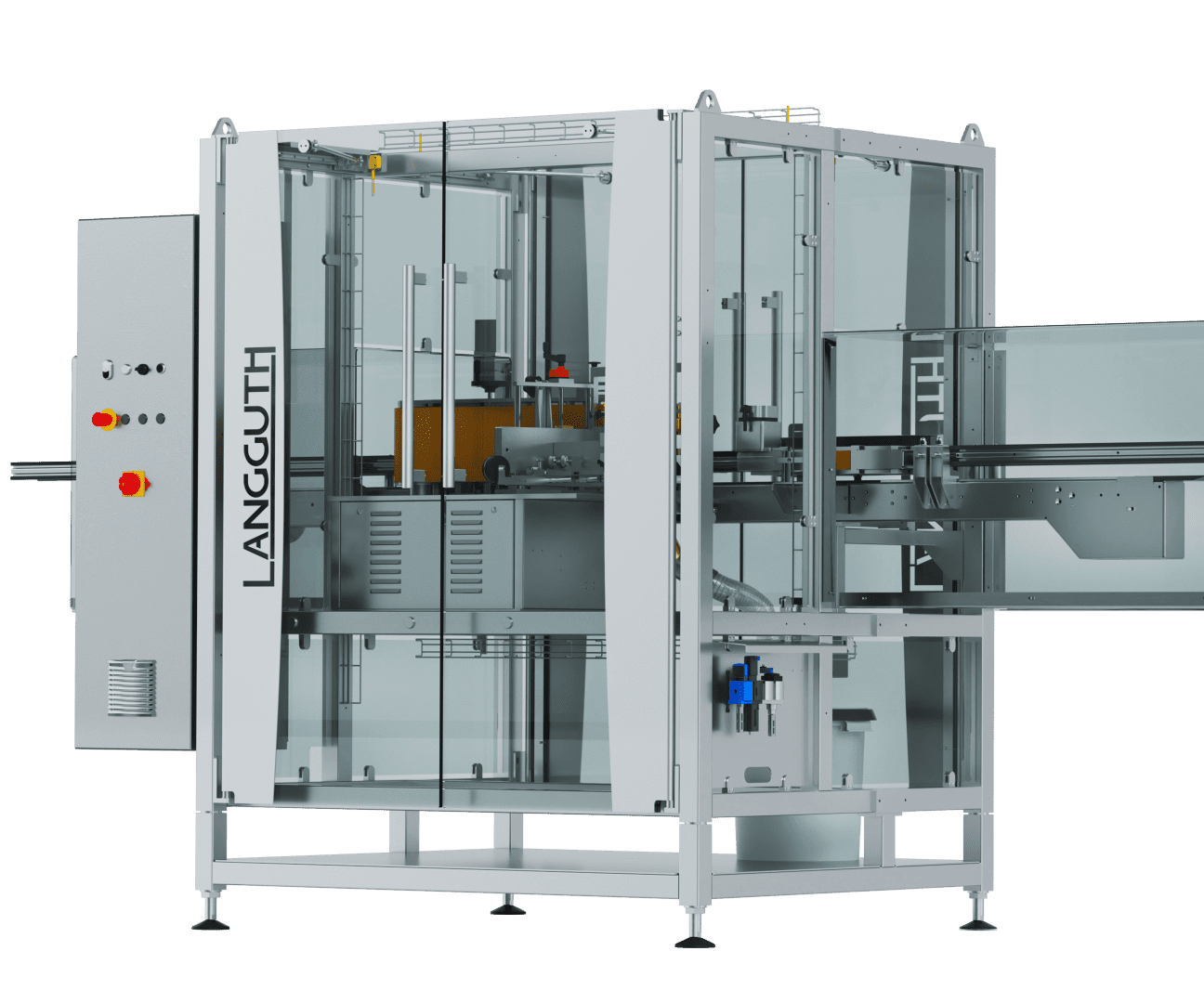

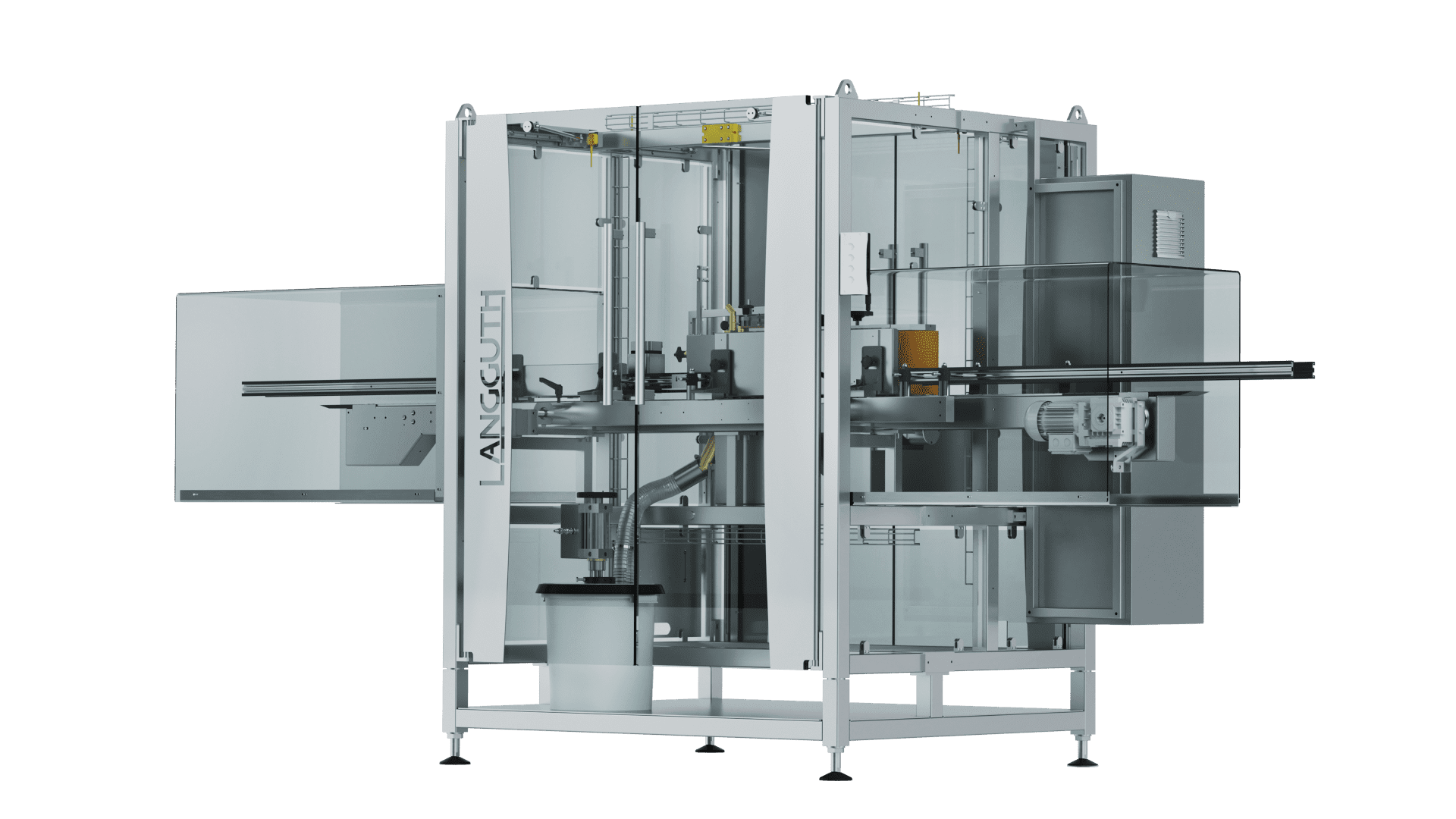

Patch and wraparound labelling

due to quick conversion and simple operation

guarantee efficient labelling

Economical in use

Low space requirements and modular design

guarantee long-term cost savings

| Base frame: | Welded in stainless steel |

| Machine dimensions: | depending on machine version L 1600 x W 1340 x H 1800 mm |

| Label magazine: | oscillating with upright label storage |

| Container type: | round containers |

| Container-Ø: | Min. 40 mm |

| Label length: | Min. 80 mm, Max. 395 mm (with adaptations max. 570 mm possible) |

| Label height: | Min. 40 mm; Max. 315 mm |

| Capacity: | 60-100 CPM max (depending on machine configuration as well as container and label sizes) |

| Conveyor elevation: | 820-920 mm |

Thanks to its comprehensive mode of operation, the wetLAN 110 labeller certainly provides a suitable solution for your industry.

In addition to main labelling, self-adhesive labellers for cap or seal labels can also be installed in combination. Common industrial printing processes mark labels individually or in batches. For the modern production line and for quality assurance, we use various control systems from sensors to camera systems.

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.